Designing Durable Flow Control Components with Asahi Kasei’s High-Performance Resins

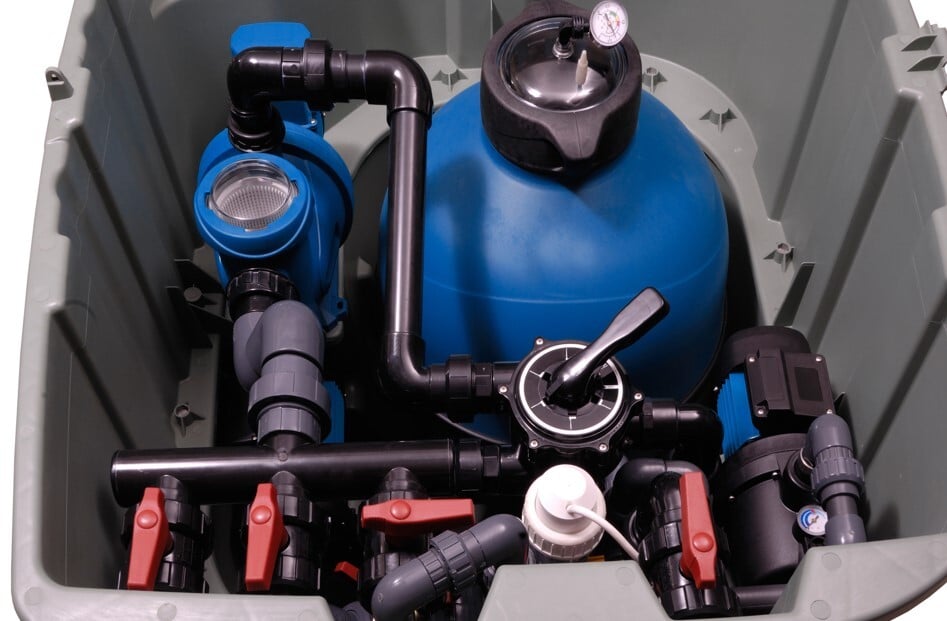

In flow control applications, reliability is everything. Whether it’s a valve regulating water pressure, a sprinkler head distributing irrigation, or a housing containing a reverse osmosis membrane, these components must perform under pressure—literally and figuratively. Failure means leaks, downtime, and potentially significant compliance risks.

That’s why leading manufacturers in the liquid handling space turn to Asahi Kasei Plastics North America (APNA) for high-performance engineered thermoplastics designed specifically for demanding fluid control environments. Our materials strike the ideal balance of mechanical strength, dimensional stability, chemical resistance, and processability.

Precision Matters in Flow Control

Flow control components are rarely simple. They require tight tolerances, consistent dimensions, and predictable performance. Even minor variances in wall thickness or material shrinkage can impact pressure regulation or lead to leaks—especially in assemblies like valves, nozzles, and meters.

APNA offers a broad portfolio of materials tailored to these needs, including:

- Thermylene® (Polypropylene): Reinforced PP blends that offer excellent chemical resistance, low density, and strong dimensional control—ideal for large housings, softener components, and low-cost valve bodies.

These resins are developed to maintain shape and performance under internal pressure, repeated cycling, and environmental stressors such as heat, humidity, or chemical exposure.

Built to Withstand Chemical & Environmental Stress

Flow control systems often operate in chemically aggressive and thermally variable environments. Think of irrigation systems that face fertilizer exposure, or reverse osmosis units that deal with mineralized and chlorinated water under constant pressure.

APNA materials are selected not just for what they can do in a lab—but for how they perform after months or years of use. Key performance attributes include:

- Low moisture absorption – reducing risk of dimensional changes or part swelling

- Chemical resistance – from common disinfectants to fertilizers and acidic solutions

- Creep and fatigue resistance – critical for parts under constant pressure or repeated actuation

- Thermal performance – maintaining stability under hot water or fluctuating temperatures

These properties ensure longevity and help manufacturers reduce field failures and warranty claims.

Consistency from Design to Mass Production

Our customers don’t just need performance—they need predictability. We support flow control component manufacturers from prototype through scale-up with:

- On-site molding and troubleshooting support to optimize cycle times and reduce scrap

- CAE (computer-aided engineering) analysis for predicting burst pressure, flow behavior, and part warpage

- Regulatory support to ensure compliance with NSF, FDA, or other relevant standards

- Customization to meet specific flow, durability, or environmental exposure needs

Whether you're building a product for potable water systems or irrigation control, our team ensures that every batch of resin performs as expected, from the first part to the millionth.

Trusted by Flow Control Leaders Across Industries

From agricultural irrigation to residential water filtration and beyond, Asahi Kasei Plastics North America’s materials are behind the scenes in millions of flow control components that customers depend on every day. OEMs partner with us not only for our advanced materials but also for our technical insight, regulatory knowledge, and manufacturing support.

If you're looking for expert guidance on selecting durable, high-performance pool & spa or liquid handling materials, our team is available to help. Contact us today to learn more about how our engineered plastics can power your next project.

Help Us. Help You

Superior Performance. White Glove Service. Unrivaled Support. Learn Why Switching to Asahi Kasei Plastics North America's materials is Stress-Free.

Share:

Tom Hanvey

\

Tom Hanvey is the Associate Director of Marketing & Sustainability at Plastics North America. Before joining APNA, he worked as the Senior Marketing Manager for Asaclean Purging Compounds. He's worked in the plastics industry for over 10 years and focuses on recyclable resins and on the inbound marketing side, providing easy-to-digest content to Tiers and OEMs looking for an edge on their competition.

Comments

\