4 Ways Advanced Plastics Power the Future of Data Centers

Introduction

Data centers are the backbone of the modern digital world, supporting everything from cloud computing to artificial intelligence. As demand for high-performance data centers grows, so do the challenges of efficiency, sustainability, and material performance. Traditional materials like metal and polycarbonate (PC) are often heavy, expensive, and inefficient for high-tech applications. At Asahi Kasei Plastics North America, we provide innovative solutions that help data center manufacturers overcome these obstacles with lightweight, flame-retardant, and high-performance engineered plastics.

-

Interior Panels & Structural Components: Reducing Weight & Increasing Efficiency

Applications: Racks, cable trays, conduits, and partitioning walls (aisle containment & airflow control).

Challenges: Metal components are heavy, increasing installation costs and carbon footprint. Polycarbonate (PC) has high material costs and CFP concerns.

Our Solution:

- XYRON™ and Thermylene® provide flame-retardant, structurally sound materials that reduce weight and streamline manufacturing.

- Injection molding options offer greater design flexibility and lower production costs.

-

Electrical Systems: Enhancing Safety & Performance

Applications: Bus ducts and connectors.

Challenges: Traditional materials (metal, PVC, and nylon) present environmental concerns, high weight, and lower heat resistance. As server performance increases, so does the need for materials that withstand high temperatures.

Our Solution:

- XYRON™ Flame Retardant & Structural Grades offer lighter weight and superior heat resistance, enhancing performance and manufacturability.

- LEONA™ PA resins provide high-heat performance (>140°C), making them ideal for connectors in high-demand server environments.

-

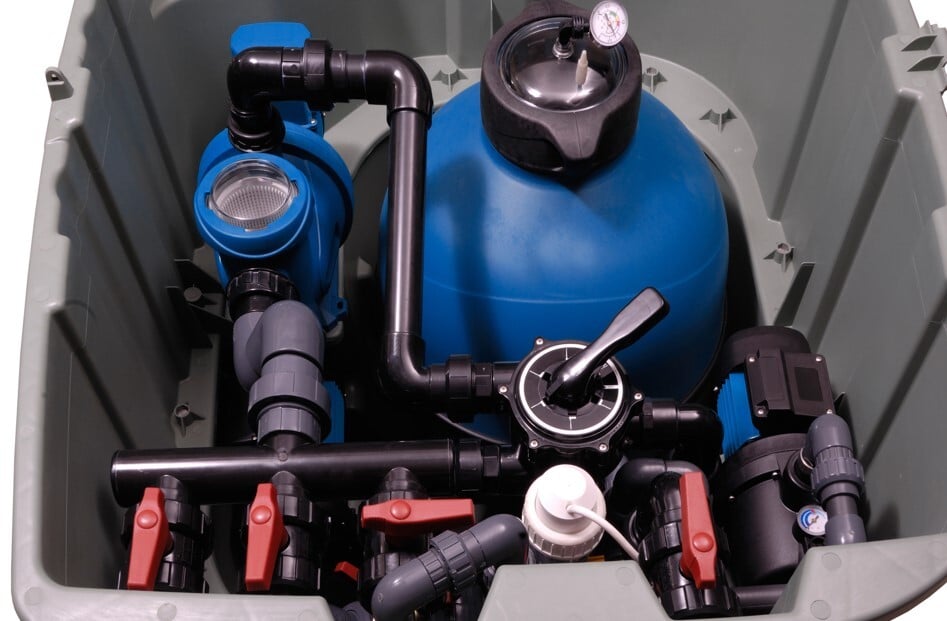

Cooling Systems: Improving Thermal Management & Durability

Applications: Pump housings, pipes, and joints.

Challenges: Metal cooling systems are prone to condensation, corrosion, and complex manufacturing processes. PPS materials, while an alternative, are expensive and difficult to process.

Our Solution:

- XYRON™, Thermylene®, and Thermylon® Glass-Filled Grades offer high-strength, corrosion-resistant, and thermally conductive materials, ensuring efficient cooling and easy manufacturing.

- These materials help reduce system weight and prevent condensation for improved cooling efficiency.

-

Energy Storage (ESS): Improving Safety & Chemical Resistance

Applications: Battery housings, covers, and formation trays.

Challenges: Polycarbonate (PC) struggles with chemical exposure, humidity resistance, and weight concerns.

Our Solution:

- XYRON™ Flame Retardant & Structural Grades provide excellent resistance to acids, solvents, and coolants, offering superior durability.

- Lowest density materials in their class ensure lightweight, high-performance energy storage solutions.

Conclusion: A Smarter Future for Data Centers

As data centers continue to evolve, the demand for lightweight, flame-retardant, and high-performance materials will only grow. At Asahi Kasei Plastics North America, we are committed to delivering innovative solutions that help data center manufacturers achieve greater efficiency, sustainability, and performance.

Are you looking for advanced material solutions for your data center applications? Contact us today to learn more about how our engineered plastics can power your next project.

Help Us. Help You

Superior Performance. White Glove Service. Unrivaled Support. Learn Why Switching to Asahi Kasei Plastics North America's materials is Stress-Free.

Share:

Tom Hanvey

\

Tom Hanvey is the Associate Director of Marketing & Sustainability at Plastics North America. Before joining APNA, he worked as the Senior Marketing Manager for Asaclean Purging Compounds. He's worked in the plastics industry for over 10 years and focuses on recyclable resins and on the inbound marketing side, providing easy-to-digest content to Tiers and OEMs looking for an edge on their competition.

Comments

\