How APNA Materials Help Water Treatment OEMs Meet Strict Regulatory Demands

Meeting regulatory demands in the water treatment industry isn’t just a box to check—it’s a critical business function. With rising environmental scrutiny, health regulations, and consumer expectations, manufacturers of water treatment systems face increasing complexity in product development. They need materials that are not only high-performing but also certified, consistent, and reliable.

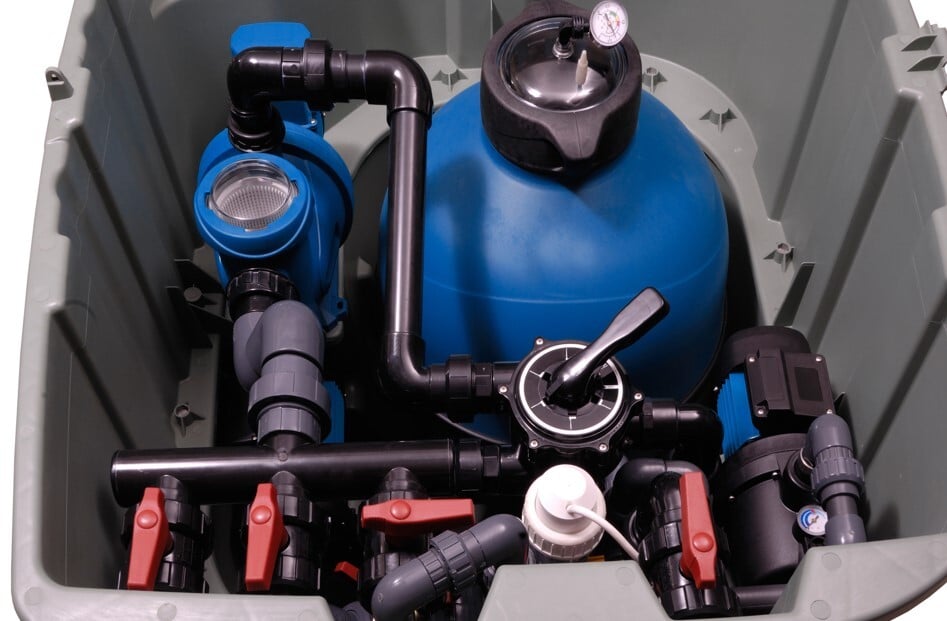

At Asahi Kasei Plastics North America (APNA), we specialize in high-performance engineered resins used across the water treatment value chain—from filtration systems and reverse osmosis units to softener tanks, flow control components, and sump pumps. Our materials are chosen by OEMs not just for compliance, but for the mechanical, chemical, and processing advantages they bring to the table.

NSF Compliance Is Just the Beginning

Most water treatment systems must comply with NSF 50, standards that govern the safety of materials in contact with drinking water. Failing these tests can result in product recalls, delayed product launches, or worse—brand damage. To meet these demands, APNA offers a range of NSF-certified materials like:

- Thermylene® (Polypropylene): Ideal for components like housings, tanks, and enclosures thanks to its strength-to-weight ratio and regulatory approval.

- XYRON™ (Modified PPE): Excellent for applications requiring low moisture uptake and dimensional stability under thermal and chemical stress.

These materials help our customers de-risk product launches by streamlining their path to NSF certification and ensuring consistent quality over large production runs.

Designed for Harsh Operating Environments

Water treatment systems are exposed to aggressive conditions—chlorinated water, extreme temperatures, and high-pressure cycling, just to name a few. Materials must retain mechanical strength, resist creep and fatigue, and perform consistently under hydrolytic stress.

APNA’s compounds are engineered for:

-

- Chemical Resistance: Essential for components exposed to disinfectants, acids, or mineral buildup. Our materials are tested for long-term exposure and compatibility.

- Dimensional Stability: Especially important in filtration housings, where precise fit ensures sealing integrity and performance.

- Low Moisture Absorption: Helps maintain mechanical properties over time, avoiding swelling or brittleness.

- Outdoor Durability: For components like pool filters and outdoor pumps, UV resistance and aesthetic retention are critical.

- Chemical Resistance: Essential for components exposed to disinfectants, acids, or mineral buildup. Our materials are tested for long-term exposure and compatibility.

Support at Every Step of the Process

Choosing the right material is only part of the equation. Getting from design to production takes deep application knowledge and technical support. That’s where APNA differentiates itself.

We provide water treatment OEMs with:

- Material Selection Guidance based on application needs and regulatory exposure

- CAE Services to simulate part performance under pressure, temperature, and fatigue

- Molding Support for process optimization and reducing scrap

- Prototype Consultation to ensure designs are scalable before tooling investment

This end-to-end support helps OEMs accelerate time-to-market while reducing design risks and operational costs.

Why Water Treatment OEMs Trust APNA

Water filtration, softening, and treatment systems are mission-critical. Product failure can lead to costly service calls, water damage, or compliance violations. OEMs turn to APNA for dependable material solutions that go beyond spec sheets.

Our commitment to performance, compliance, and customer success makes us a trusted partner for manufacturers across North America. Whether you're building the next generation of energy-efficient sump pumps or high-flow reverse osmosis systems, APNA has the materials—and the know-how—to help you succeed.

Ready to improve the performance of your parts in water applications? Contact us today to learn more about how our engineered plastics can power your next project.

Help Us. Help You

Superior Performance. White Glove Service. Unrivaled Support. Learn Why Switching to Asahi Kasei Plastics North America's materials is Stress-Free.

Share:

Tom Hanvey

\

Tom Hanvey is the Associate Director of Marketing & Sustainability at Plastics North America. Before joining APNA, he worked as the Senior Marketing Manager for Asaclean Purging Compounds. He's worked in the plastics industry for over 10 years and focuses on recyclable resins and on the inbound marketing side, providing easy-to-digest content to Tiers and OEMs looking for an edge on their competition.

Comments

\