The Evolution of Connectors: Meeting the Demands of Modern Electronics

Connectors are the unsung heroes of modern electronics, enabling the seamless transmission of electrical power and signals between various devices. As electronic systems become more complex and multifunctional, the demand for high-performance connectors has grown, leading to significant advancements in materials and design.

The Early Days: Simple Connections

In the early stages of electronic development, connectors were basic components designed to establish and maintain electrical continuity. These early connectors were primarily used in telecommunication and electrical power distribution, with limited design variations. As electronic devices evolved, the need for more specialized connectors arose, requiring enhancements in durability, electrical properties, and safety standards.

The Expansion Across Industries

The rapid technological advancements across industries have driven the diversification of connectors.

- Automotive Industry: Modern vehicles rely on connectors to link electronic control units (ECUs) with sensors and actuators, enabling engine management, safety features, and infotainment systems. The rise of electric vehicles (EVs) has further increased demand for connectors capable of handling high voltage and high current applications.

- Consumer Electronics: The explosion of smartphones, tablets, and wearable devices has led to the development of miniaturized, high-speed connectors that support rapid data transfer and efficient power delivery.

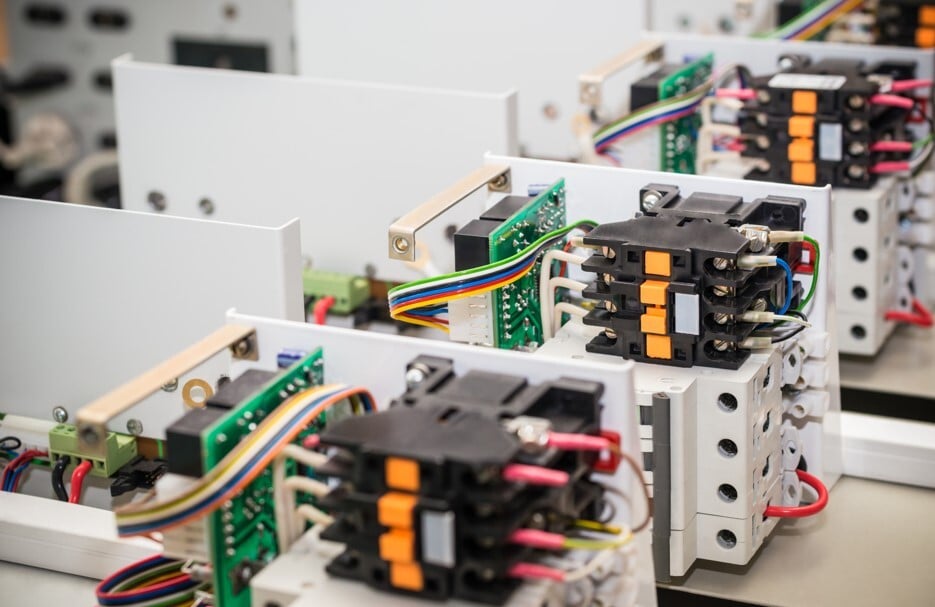

- Industrial Applications: Connectors in industrial environments must withstand extreme temperatures, mechanical stress, and exposure to chemicals. Robust materials that enhance durability and reliability are essential for applications in automation, robotics, and power transmission.

Material Innovations: Enhancing Performance and Sustainability

The evolution of connectors is not solely about improved design but also about material innovations that enhance functionality and sustainability.

- Flame Retardancy and Electrical Properties: As connectors are increasingly used in high-power applications, materials with superior flame resistance, glow wire ignition temperature (GWIT), and comparative tracking index (CTI) are crucial for safety and performance.

- Environmental Considerations: With growing concerns about sustainability and workplace safety, the demand for halogen-free and red phosphorus-free materials has risen.

- Advanced Engineering Plastics: High-performance materials such as Asahi Kasei's LEONA™ SN Series offer exceptional durability, heat resistance, and safety compliance while eliminating hazardous substances. These materials provide excellent laser marking, high tracking resistance, and superior mechanical retention under wet conditions, making them ideal for modern connector applications.

The Future of Connectors

As industries continue to evolve, the future of connectors will be shaped by trends such as:

- Miniaturization: As devices become smaller and more powerful, connectors must accommodate higher data transfer speeds and compact designs.

- Increased Power Requirements: The shift toward electrification in automotive and industrial applications will drive demand for high-current and high-voltage connectors.

- Sustainability: Manufacturers will continue to focus on environmentally friendly materials and energy-efficient production methods to meet global sustainability goals.

Conclusion

The evolution of connectors reflects the ever-changing landscape of modern electronics. From simple electrical links to highly specialized components, connectors have adapted to meet the increasing demands of advanced technologies. By leveraging innovative materials like LEONA™ SN Series, manufacturers can ensure that connectors remain reliable, durable, and environmentally friendly for years to come.

If you're looking for expert guidance on selecting durable, high-performance connector materials, our team is available to help. Contact us today to learn more about how our engineered plastics can power your next project.

Help Us. Help You

Superior Performance. White Glove Service. Unrivaled Support. Learn Why Switching to Asahi Kasei Plastics North America's materials is Stress-Free.

Share:

Tom Hanvey

\

Tom Hanvey is the Associate Director of Marketing & Sustainability at Plastics North America. Before joining APNA, he worked as the Senior Marketing Manager for Asaclean Purging Compounds. He's worked in the plastics industry for over 10 years and focuses on recyclable resins and on the inbound marketing side, providing easy-to-digest content to Tiers and OEMs looking for an edge on their competition.

Comments

\